Cold Work Tool Steel

-

Hot

1.2379 Cold Work Tool Steel

This alloy is one of the Cold Work, high carbon, high chromium type tool steels. D2 is a deep hardening, highly wear resistant alloy. It hardens upon air cooling so as to have minimum distortion after heat treatment.

Email Details -

1.2601 Cold Work Tool Steel

Ledeburitic Cr-steel for high performance cutting tools, toughness better than D3, possibility of nitriding. This alloy possesses a very high compressive strength and is deep hardening.

Email Details -

1.2080 Cold Work Tool Steel

D3 is an oil hardening, high carbon/chromium type tool steel with very high wear resistance. It hardens with a very slight change in size. The alloy possesses very high compressive strength and is deep hardening.

Email Details -

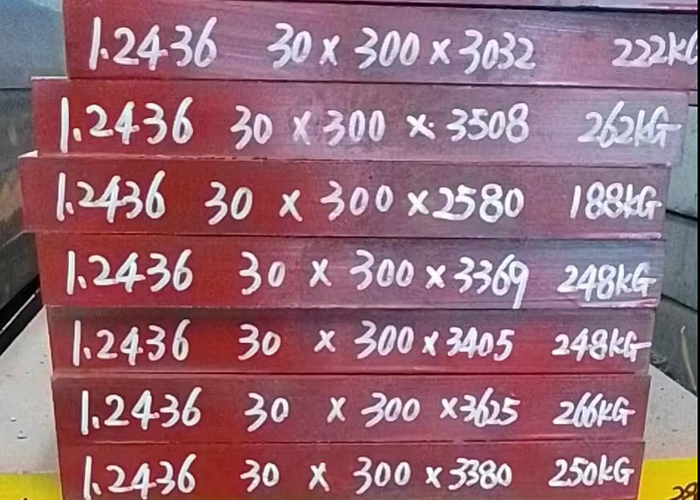

1.2436 Cold Work Tool Steel

Ledeburitic chromium steel with high durability and cutting performance; low distortion on hardening.

Email Details -

D7 Cold Work Tool Steel

High carbon and high chromium air hardening tool steel, extremely resistant to wear, strong toughness, high compressive strength. Its material uniformity, small grain.

Email Details -

Hot

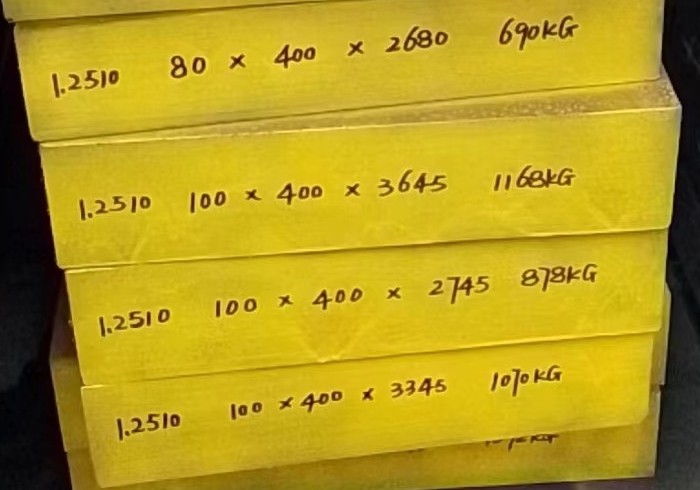

1.2510 Cold Work Tool Steel

This alloy is one of the cold work, oil hardening type tool steels. It is relatively inexpensive containing small amounts of manganese, tungsten and chromium. Hardening by oil quench minimizes distortion and cracking.

Email Details -

1.2842 Cold Work Tool Steel

Oil quenched tool steel, not easy to crack, heat treatment is not easy to deformation. Wear resistance, strong hardness, easy machining, simple heat treatment, excellent cutting performance.

Email Details -

Hot

1.2363 Cold Work Tool Steel

This alloy is one of the cold work, medium air hardening type tool steels. It contains chromium and molybdenum with a relatively high (1 %) carbon content and is capable of deep hardening from air quench so as to minimize distortion.

Email Details -