1.2379 Cold Work Tool Steel

This alloy is one of the Cold Work, high carbon, high chromium type tool steels. D2 is a deep hardening, highly wear resistant alloy. It hardens upon air cooling so as to have minimum distortion after heat treatment.

Properties:

● Vacuum degassing, pure steel, spheroidized annealing suitable for cutting, no quenching cracking, superior wear resistance and toughness.

Applications:

● Widely used in the thickness of less than 2mm plate, stamping die, punching die, forming die, trimming die, thread rolling die, woodworking blade, food processing tools and measuring tools.

Parameters

Grade | Chemical Composition (%) | |||||||||

C | Si | Mn | Cr | Mo | V | P | S | |||

GB | Cr12Mo1V1 | 1.40~1.60 | ≦0.60 | ≦0.60 | 11.0~13.0 | 0.70~1.20 | 0.50~1.10 | ≦0.03 | ≦0.03 | |

ASTM | D2 | 1.40~1.60 | 0.10~0.60 | 0.20~0.60 | 11.0~13.0 | 0.70~1.20 | 0.50~1.10 | ≦0.03 | ≦0.03 | |

DIN | 1.2379 | 1.40~1.60 | ≦0.60 | ≦0.60 | 11.0~13.0 | ≧0.70 | ≧0.70 | ≦0.03 | ≦0.03 | |

JIS | SKD11 | 1.40~1.60 | ≦0.40 | ≦0.60 | 11.0~13.0 | 0.80~1.20 | 0.20~0.50 | ≦0.03 | ≦0.03 | |

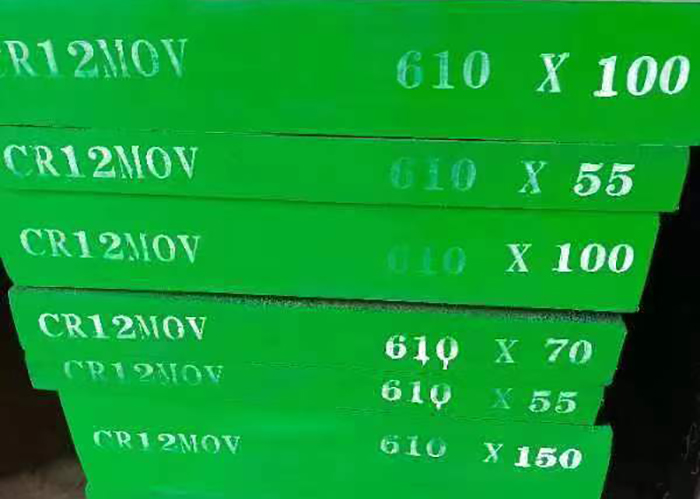

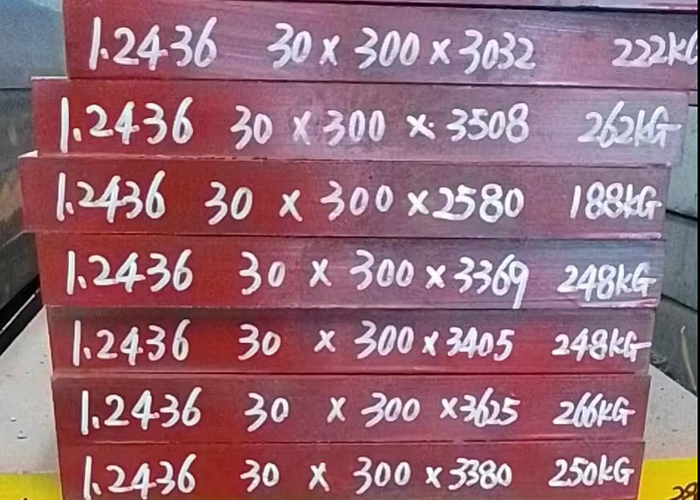

| Specification | Round BarØ (mm) | Flat Bar (mm) | ||||||||

Hot Rolled | Hot Forged | EAF | ESR | |||||||

Ø12~Ø50 | EAF | ESR | Thickness | 20~200 | 20~450 | |||||

Ø50~Ø250 | Ø50~Ø650 | width | 80~610 | 610max | ||||||

FORMING

Forming is done by forging and machining.

HEAT TREATMENT

Preheat very slowly to 1500 F and then increase temperature to 1850 F. Hold at 1850 F for 20 to 45 minutes and air cool (air quench).

FORGING

Forging may be done in the range of 1950 F down to 1750 F. Do not forge below 1700 F.

COLD WORKING

Cold working by conventional methods may be done with the alloy in the annealed condition.

ANNEALING

Anneal at 1600 F to 1650 F followed by slow furnace cooling at 40 F per hour or less.

TEMPERING

Tempering may be done in the range of 400 F for Rockwell C 61 to 1000 F for Rockwell C 54.