1.2344 Hot Work Tool Steel

This alloy is one of the hot work, chromium type tool steels. It also contains molybdenum and vanadium as strengthening agents. The chromium content assists this alloy to resist softening if used at higher temperatures. Secondary hardening steels with good tempering resistance. It maintains high hardness and strength at elevated temperatures. Good resistance to thermal fatigue, erosion and wear. Steel with very high toughness and good ductility and harden-ability. Tools can be water cooled.

Properties:

● Good toughness, high temperature resistance, excellent cutting performance and polishing performance. After EAF smelting and ESR remelting, the steel quality is better.

Applications:

● Suitable for Aluminum, Zinc, Copper alloy extrusion die, Die casting die, hot forging die and hot scissors. It is also suitable for making plastic mold with high yield.

Chemical composition (%):

Steel grade | C | Si | Mn | Cr | Mo | V | P | S | ||

GB | 4Cr5MoSiV1 | 0.32~0.42 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.75 | 0.80~1.20 | ≦0.03 | ≦0.03 | |

ASTM | H13 | 0.32~0.45 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.75 | 0.80~1.20 | ≦0.03 | ≦0.03 | |

DIN | 1.2344 | 0.37~0.42 | 0.90~1.20 | 0.30~0.50 | 4.80~5.50 | 1.20~1.50 | 0.90~1.10 | ≦0.03 | ≦0.02 | |

JIS | SKD61 | 0.35~0.42 | 0.80~1.20 | 0.25~0.50 | 4.80~5.50 | 1.00~1.50 | 0.80~1.15 | ≦0.03 | ≦0.02 | |

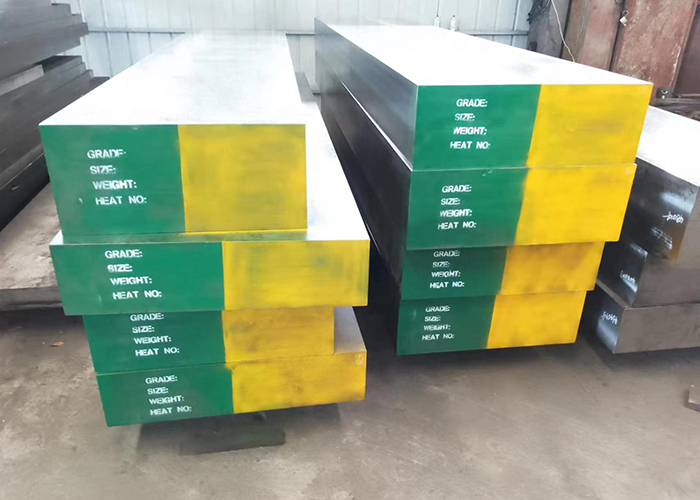

Specification

Specification | Round bar (mm) | Flat bar (mm) | ||||

Hot Rolled | Hot Forged | Hot Forged | ||||

Ø12~Ø50 | EAF | ESR | EAF | ESR | ||

Ø50~Ø250 | Ø50~Ø650 | Thickness | 20~200 | 20~450 | ||

width | 80~610 | 680max | ||||

Physical properties (average values) at ambient temperature

Modulus of elasticity [103 x N/mm2]: 215

Density [g/cm3]: 7.78

Thermal conductivity [W/m.K]: 25.0

Electric resistivity [Ohm mm2/m]: 0.52

Specific heat capacity[J/g.K]: 0.46

Soft Annealing

Heat to 760-810oC, cool slowly in furnace. This will produce a maximum Brinell hardness of 229.

Hardening

Harden from a temperature of 1020-1060oC followed by oil, air quenching or warm bath (450-550oC). Hardness after quenching is 52-56 HRC.

Tempering Temperature (oC) vs. Hardness (HRC) vs. Tensile Stregth (N/mm2)

100oC | 200oC | 300oC | 400oC | 500oC | 550oC | 600oC | 650oC | 700oC |

53 | 52 | 51 | 52 | 54 | 53 | 50 | 43 | 31 |

1845 | 1790 | 1730 | 1790 | 1910 | 1845 | 1680 | 1360 | 995 |