1.2510 Cold Work Tool Steel

This alloy is one of the cold work, oil hardening type tool steels. It is relatively inexpensive containing small amounts of manganese, tungsten and chromium. Hardening by oil quench minimizes distortion and cracking.

Properties:

● Vacuum degassing, pure steel, spheroidizing annealing suitable for cutting, high quenching hardness, stable tempering size.

Applications:

● Recommended applications include cold forming dies, punching dies, bending dies, forming rolls, reamer, knurling tools, and measuring tools.

Parameters

Grade | Chemical Composition (%) | |||||||||

C | Si | Mn | Cr | V | P | S | W | |||

GB | 9CrWMn | 0.85~0.90 | ≦0.40 | 0.90~1.20 | 0.50~0.80 | - | ≦0.03 | ≦0.03 | 0.50~0.80 | |

ASTM | O1 | 0.85~1.00 | 0.10~0.60 | 1.00~1.40 | 0.40~0.60 | ≦0.30 | ≦0.03 | ≦0.03 | 0.40~0.60 | |

DIN | 1.2510 | 0.90~1.05 | 0.15~0.35 | 1.00~1.20 | 0.50~0.70 | 0.05~0.15 | ≦0.035 | ≦0.035 | 0.50~0.70 | |

ISO | 2140 | 0.85~1.00 | 0.20~0.40 | 1.10~1.30 | 0.40~0.60 | 0.05~0.15 | ≦0.03 | ≦0.02 | 0.40~0.60 | |

JIS | SKS3 | 0.90~1.00 | ≦0.35 | 0.90~1.20 | 0.50~1.00 | - | ≦0.03 | ≦0.03 | 0.50~1.00 | |

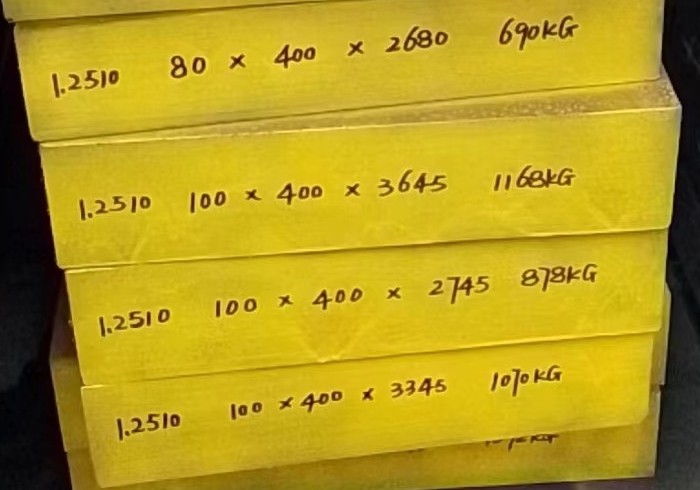

Specification | Round BarØ (mm) | Flat Bar (mm) | ||||||||

Hot Rolled | Hot Forged | EAF | ESR | |||||||

Ø12~Ø50 | EAF | ESR | Thickness | 20~200 | 20~450 | |||||

Ø50~Ø250 | Ø50~Ø650 | width | 80~610 | 610max | ||||||

Physical properties (average values) at ambient temperature

Density [g/cm3]: 7.85

Thermal conductivity [W/m.K]: 30.0

Soft Annealing

Heat to 740-770oC, cool slowly in furnace. This will produce a maximum Brinell hardness of 230.

Hardening

Harden from a temperature of 780-820oC followed by oil, warm bath (180-220oC) quenching. Hardness after quenching is 64 HRC.

Tempering Temperature (oC) vs. Hardness (HRC)

100oC | 200oC | 300oC | 400oC | 500oC | 600oC | 650oC |

64 | 61 | 56 | 51 | 44 | 37 | 34 |

Forging

Hot forming temperature: 1037-875oC.