1.2842 Cold Work Tool Steel

Oil quenched tool steel, not easy to crack, heat treatment is not easy to deformation. Wear resistance, strong hardness, easy machining, simple heat treatment, excellent cutting performance.

Properties:

● Oil quenched tool steel, not easy to crack, heat treatment is not easy to deformation. Wear resistance, strong hardness, easy machining, simple heat treatment, excellent cutting performance.

Applications:

● Widely used in the production of various tools, used in wood industry, paper industry and metal processing industry, cold shear blades, thread cutting tools, cold molding die, plastic compression die, rubber compression die and reamer.

Parameters

Grade | Chemical Composition (%) | |||||||||

C | Si | Mn | Cr | Mo | V | P | S | |||

GB | 9Mn2V | 0.85~0.95 | ≦0.40 | 1.70~2.00 | - | - | 0.10~0.25 | ≦0.03 | ≦0.03 | |

ASTM | O2 | 0.85~0.95 | ≦0.50 | 1.40~1.80 | ≦0.50 | ≦0.30 | ≦0.30 | ≦0.03 | ≦0.03 | |

DIN | 1.2842 | 0.85~0.95 | 0.10~0.40 | 1.80~2.20 | 0.20~0.50 | - | 0.05~0.15 | ≦0.03 | ≦0.03 | |

JIS | SKS93 | 1.00~1.10 | ≦0.50 | 0.80~1.10 | 0.20~0.60 | - | - | ≦0.03 | ≦0.03 | |

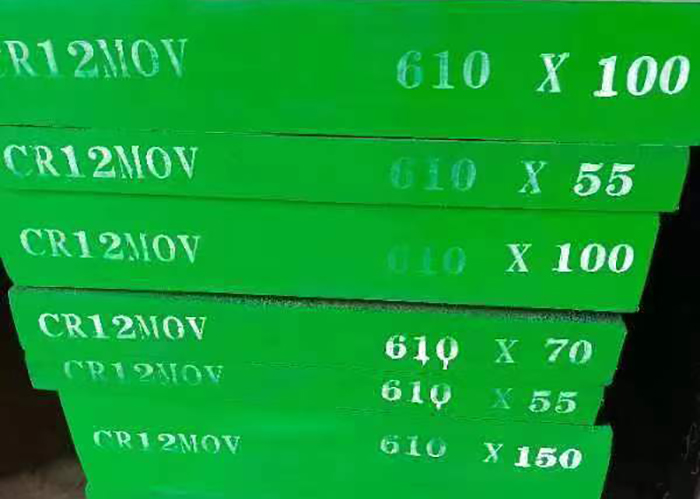

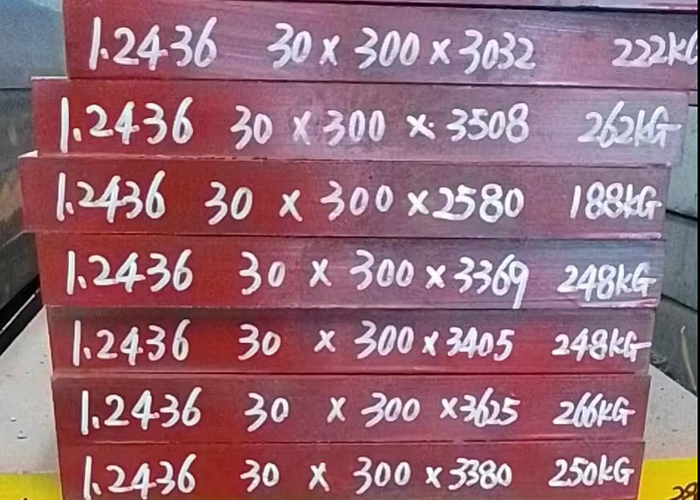

Specification | Round BarØ (mm) | Flat Bar (mm) | ||||||||

Hot Rolled | Hot Forged | EAF | ESR | |||||||

Ø12~Ø50 | EAF | ESR | Thickness | 20~200 | 20~450 | |||||

Ø50~Ø250 | Ø50~Ø650 | width | 80~610 | 610max | ||||||