1.2363 Cold Work Tool Steel

This alloy is one of the cold work, medium air hardening type tool steels. It contains chromium and molybdenum with a relatively high (1 %) carbon content and is capable of deep hardening from air quench so as to minimize distortion.

Properties:

● Vacuum degassing, pure steel, ball fire degradation suitable for cutting, good wear resistance, strong toughness.

Applications:

● Suitable for complex or high precision die, stamping die, claw chuck, woodworking cutting tools, injection tools, hammer, industrial cutting tools and measuring tools.

Parameters

Grade | Chemical Composition (%) | |||||||||

C | Si | Mn | Cr | Mo | V | P | S | |||

GB | Cr5Mo1V | 0.95~1.05 | ≦0.50 | ≦1.00 | 4.75~5.50 | 0.90~1.40 | 0.15~0.50 | ≦0.03 | ≦0.03 | |

ASTM | A2 | 0.95~1.05 | 0.10~0.50 | 0.40~1.00 | 4.75~5.50 | 0.90~1.40 | 0.15~0.50 | ≦0.03 | ≦0.03 | |

DIN | 1.2363 | 0.90~1.05 | 0.20~0.40 | 0.40~0.70 | 4.80~5.50 | 0.90~1.20 | 0.10~0.30 | ≦0.03 | ≦0.03 | |

ISO | 2260 | 0.95~1.05 | 0.15~0.30 | 0.45~0.75 | 5.00~5.50 | 1.00~1.20 | 0.15~0.25 | ≦0.03 | ≦0.02 | |

JIS | SKD12 | 0.95~1.05 | ≦0.40 | 0.60~0.90 | 4.50~5.50 | 0.80~1.20 | 0.20~0.50 | ≦0.03 | ≦0.03 | |

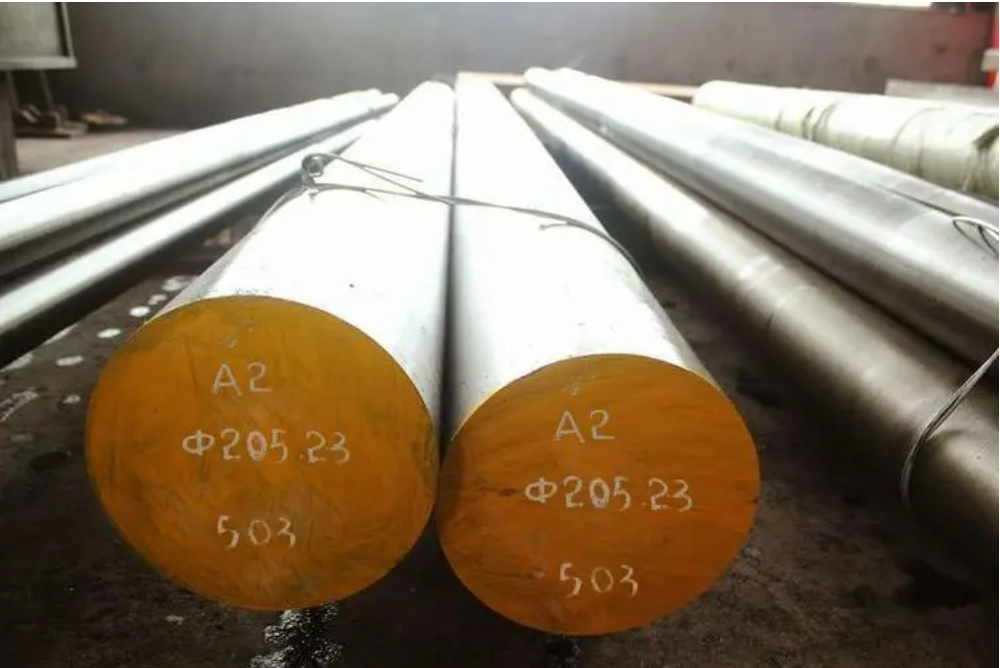

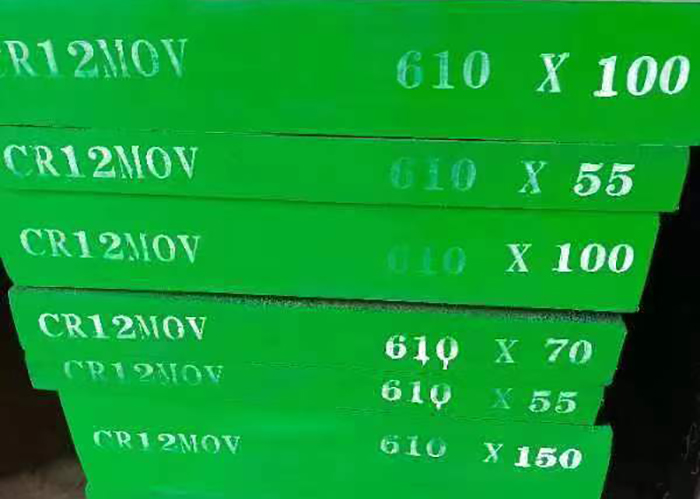

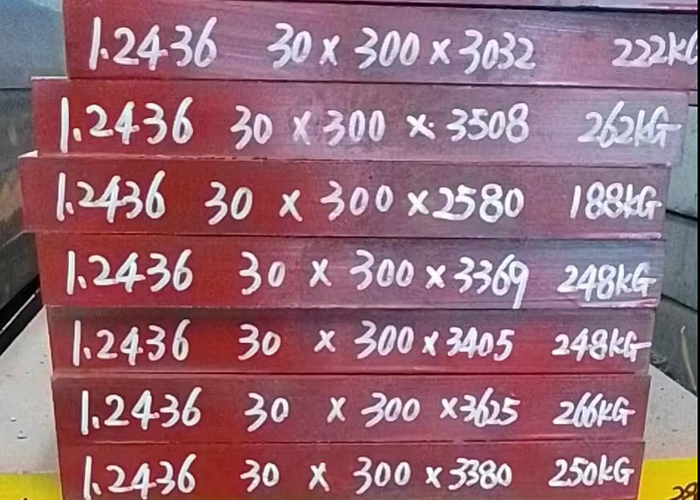

Specification | Round BarØ (mm) | Flat Bar (mm) | ||||||||

Hot Rolled | Hot Forged | EAF | ESR | |||||||

Ø12~Ø50 | EAF | ESR | Thickness | 20~200 | 20~450 | |||||

Ø50~Ø250 | Ø50~Ø650 | width | 80~610 | 610max | ||||||

Physical properties (average values) at ambient temperature

Density [g/cm3]: 7.70

Thermal conductivity [W/m.K]: 26.0

Soft Annealing

Heat to 800-840oC, cool slowly in furnace. This will produce a maximum Brinell hardness of 230.

Stress Relieving

Stress relieving to remove machining stresses should be carried out by heating to 650oC, holding for one hour at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening

Harden from a temperature of 930-970oC followed by air, oil, warm bath (500-550oC) quenching. Hardness after quenching is 63 HRC.

Tempering

Tempering temperature: 150-550oC

Tempering Temperature (oC) vs. Hardness (HRC)

100oC | 200oC | 300oC | 400oC | 500oC | 600oC | 700oC |

63 | 62 | 58 | 57 | 57 | 51 | 36 |

Forging

Hot forming temperature: 1050-850oC.

Corrosion Resistance

Corrosion resistance of this alloy is better than that of plain carbon steels. However it will rust unless given protective treatment.

Welding

This is an alloy steel and thus capable of being welded.