1.2738 Plastic Mold Steel

This steel is in the category generally labeled as Mold Steels. Nickel and chromium are the alloying elements for hardness and toughness. Cold work tool steel with good machinability, excellent polishability, suitable for texturing. Improved through hardenability comapred to 1.2311.

Properties:

● Excellent mirror polishing performance, pre-hard state delivery, no need for reheat treatment can be directly engraving processing; The size and hardness of the annealing and surface desalinization have little change.

Applications:

● Large plastic products such as household appliances, computer shell mold, telephone, speaker, PMMA products, etc.

Parameters

Grade | Chemical Composition (%) | |||||||||

C | Si | Mn | Cr | Mo | P | S | ||||

GB | 3Cr2NiMo | 0.32~0.40 | 0.20~0.40 | 0.60~0.80 | 1.70~2.00 | 0.25~0.40 | ≦0.03 | ≦0.03 | ||

ASTM | P20+Ni | 0.28~0.40 | 0.20~0.80 | 0.60~1.00 | 1.40~2.00 | 0.30~0.55 | ≦0.03 | ≦0.03 | ||

DIN | 1.2738 | 0.35~0.45 | 0.20~0.40 | 1.30~1.60 | 1.80~2.10 | 0.15~0.25 | ≦0.03 | ≦0.03 | ||

ISO | 718 | 0.33~0.37 | 0.15~0.35 | 0.60~1.00 | 1.65~1.75 | 0.40~0.50 | ≦0.03 | ≦0.03 | ||

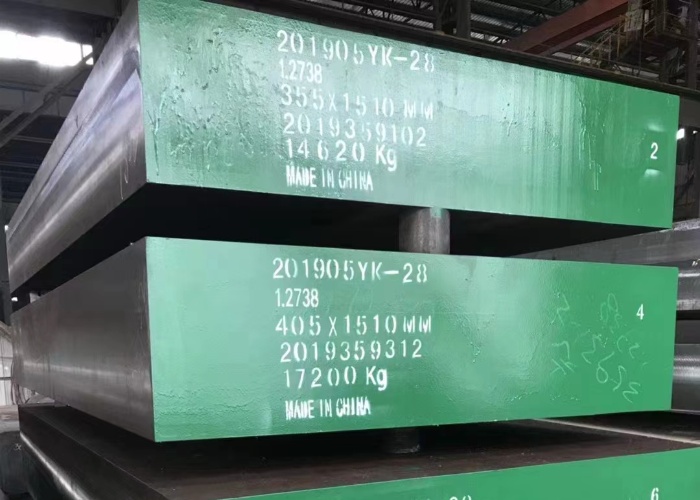

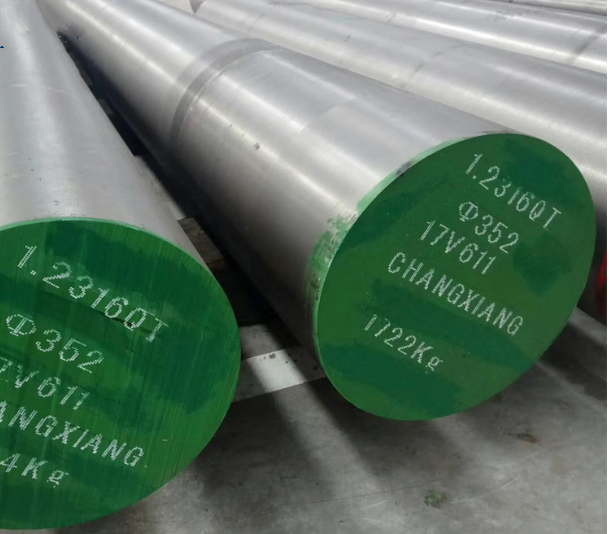

Specification | Round BarØ (mm) | Flat Bar (mm) | ||||||||

Hot Rolled | Hot Forged | EAF | ESR | |||||||

Ø12~Ø50 | EAF | ESR | Thickness | 20~200 | 20~450 | |||||

Ø50~Ø250 | Ø50~Ø650 | width | 105~610 | 610max | ||||||

Physical properties (average values) at ambient temperature

Modulus of elasticity [103x N/mm2]: 205

Density [g/cm3]: 7.80

Thermal conductivity [W/m.K]: 29.0

Specific heat capacity[J/g.K]: 0.46

Soft Annealing

Heat to 710-740oC, cool slowly. This will produce a maximum Brinell hardness of 235.

Stress Relieving

Stress relieving to remove machining stresses should be carried out by heating to 650oC, holding for one hour at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening

Harden from a temperature of 840-880oC followed by oil, air ot warm bath (180-220oC) quenching. Hardness after quenching is 52 HRC.

Tempering Temperature (oC) vs. Hardness (HRC) vs. Tensile Stregth (N/mm2)

100oC | 200oC | 300oC | 400oC | 500oC | 600oC | 700oC |

52 | 51 | 49 | 46 | 42 | 36 | 28 |

1790 | 1730 | 1620 | 1480 | 1330 | 1140 | 920 |

Forging

Hot forming temperature: 1093-898oC.