1.2083 Plastic Mold Steel

Corrosion resistance, excellent polishing performance, pre-hard treatment does not need heat treatment, suitable for direct die engraving processing.

Properties

● Corrosion resistance, excellent polishing performance, pre-hard treatment does not need heat treatment, suitable for direct die engraving processing.

Applications:

● Suitable for all kinds of plastic products mold, more suitable for special requirements of mold (weak acid or humid environment mold), transparent plastic products mold.

Parameters

Grade | Chemical Composition (%) | |||||||||

C | Si | Mn | Cr | Ni | P | S | ||||

GB | 4Cr13 | 0.36~0.45 | ≦0.60 | ≦0.80 | 12.00~14.00 | ≦0.60 | ≦0.030 | ≦0.030 | ||

AISI | 420 | 0.38~0.42 | ≦0.60 | ≦0.60 | 12.5~13.5 | ≦0.60 | ≦0.030 | ≦0.030 | ||

DIN | 1.2083 | 0.38~0.42 | ≦0.60 | ≦1.00 | 12.5~13.5 | ≦0.60 | ≦0.030 | ≦0.030 | ||

JIN | SUS420J2 | 0.38~0.43 | ≦0.60 | ≦1.00 | 12.5~13.5 | ≦0.60 | ≦0.030 | ≦0.030 | ||

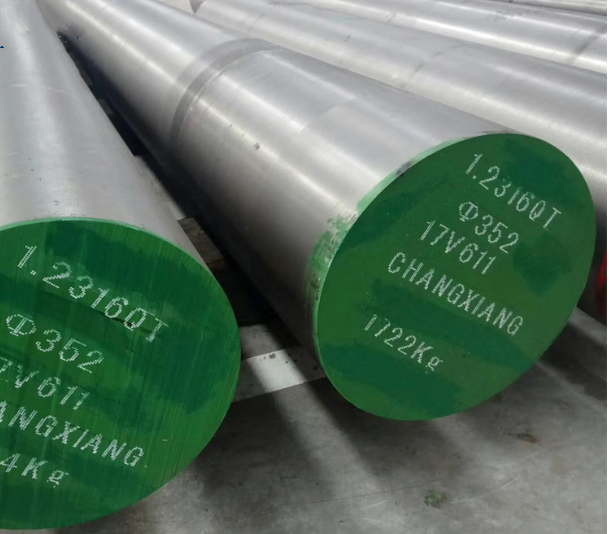

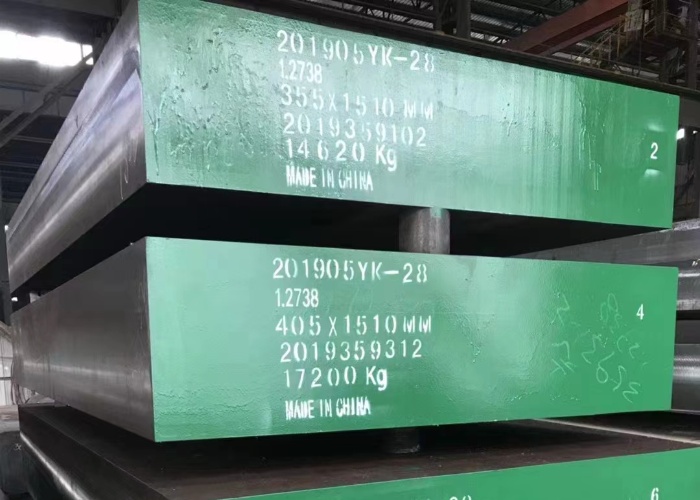

Specification | Round BarØ (mm) | Flat Bar (mm) | ||||||||

Hot Rolled | Hot Forged | EAF | ESR | |||||||

Ø12~Ø50 | EAF | ESR | Thickness | 20~200 | 20~450 | |||||

Ø50~Ø250 | Ø50~Ø650 | width | 105~610 | 610max | ||||||