1.2316 Plastic Mold Steel

Martensitic plastic die steel. With strong corrosion resistance, uniform material, wear resistance, easy to process, good polishing performance.

Hot rolled or forged condition, annealing or Pre-harden, black or machined surface

Hardness: ≤229HBS or 32~36HRC

Hot rolled technology: EAF+LF+VD

Forged technology: EAF+LF+VD+ESR+Forging +Q T + Machined surface

hot treatment quench :1020-1050°C,oil cooling or quenching liquid colling,hardnessHRC≥45

Tempering:temperture (°C):, 100, 200, 300, 400, 500, 600

Hardness (HRC): 28~36

Ultrasonic test standards: Sep1921-84,Gr.3, Class D/d or E/e

Properties:

● Martensitic plastic die steel. With strong corrosion resistance, uniform material, wear resistance, easy to process, good polishing performance.

Applications:

● It is widely used in gap die, contour die, fall forging tool, blow mold, Mosaic die; Can also be used to resist chemical corrosion and abrasive plastic mold.

Parameters

Grade | Chemical Composition (%) | |||||||||

C | Si | Mn | Cr | Mo | P | S | Ni | |||

GB | 3Cr17NiMo | 0.30~0.40 | ≦1.00 | ≦1.00 | 16.0~17.5 | 0.80~1.30 | ≦0.03 | ≦0.03 | 0.60~1.00 | |

DIN | 1.2316 | 0.33~0.43 | ≦1.00 | ≦1.00 | 15.0~17.0 | 1.00~1.30 | ≦0.03 | ≦0.03 | ≦1.00 | |

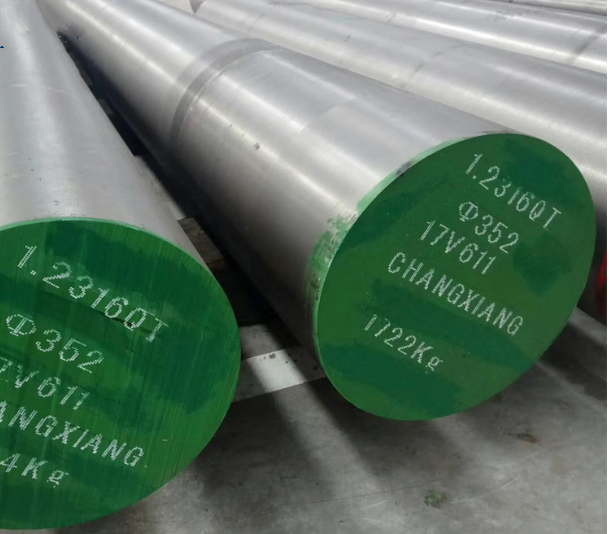

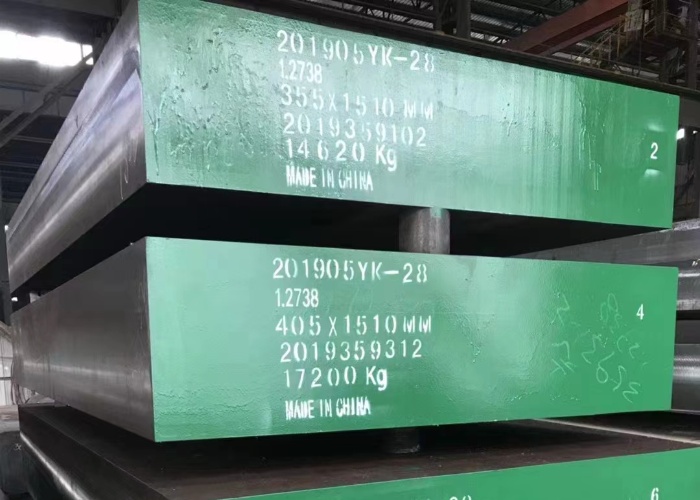

Specification | Round BarØ (mm) | Flat Bar (mm) | ||||||||

Hot Rolled | Hot Forged | EAF | ESR | |||||||

Ø12~Ø50 | EAF | ESR | Thickness | 20~200 | 20~450 | |||||

Ø50~Ø300 | Ø50~Ø650 | width | 105~610 | 610max | ||||||