S7 Cold Work Tool Steel

S7 is a general purpose air hardening tool steel having high impact and shock resistance. It has good resistance to softening at moderately high temperatures. This combination of properties makes it suitable for many hot-work and cold-work applications.

Properties:

● S7 steel is an impact resistant tool steel that can be air-cooled hardened or oil-cooled quenched. Strong impact toughness, wear resistance; Easy to cut, good polishing performance.

Applications:

● It can be used to make cold working tools that need to resist impact force and impact load, such as shear blades, forging dies, chisels and punching machines. It can also be used to operate hot tools whose temperature is not higher than 538℃.

Parameters

Grade | Chemical Composition (%) | |||||||||

C | Si | Mn | Cr | Mo | V | P | S | |||

GB | 5Cr3Mn1SiMo1V1 | 0.45~0.55 | 0.20~1.00 | 0.20~0.90 | 3.00~3.50 | 1.30~1.80 | ≦0.35 | ≦0.03 | ≦0.03 | |

ASTM | S7 | 0.45~0.55 | 0.20~1.00 | 0.20~0.90 | 3.00~3.50 | 1.30~1.80 | ≦0.35 | ≦0.03 | ≦0.03 | |

DIN | 1.2357 | 0.45~0.55 | 0.20~0.50 | 0.20~0.80 | 3.00~3.60 | 1.30~1.60 | 0.05~0.25 | ≦0.03 | ≦0.03 | |

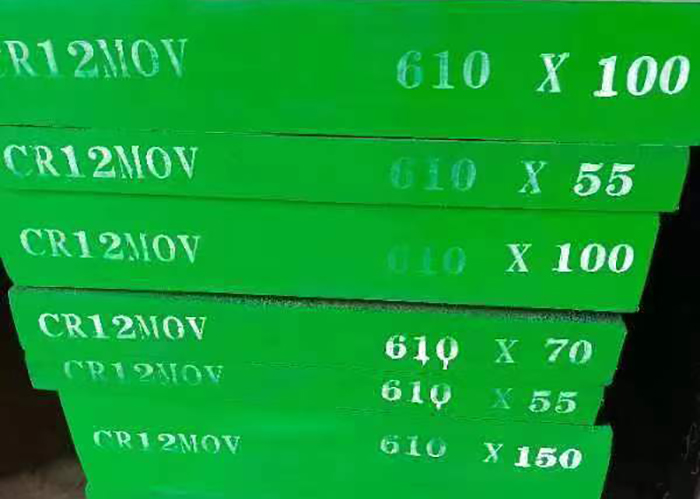

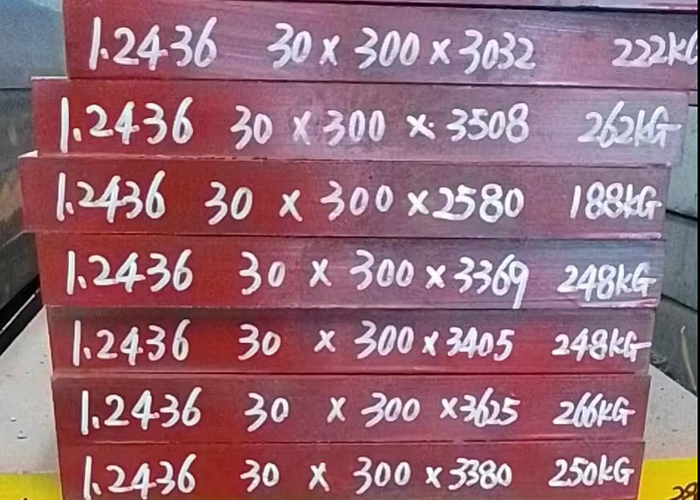

Specification | Round BarØ (mm) | Flat Bar (mm) | ||||||||

Hot Rolled | Hot Forged | EAF | ESR | |||||||

Ø12~Ø50 | EAF | ESR | Thickness | 20~200 | 20~450 | |||||

Ø50~Ø250 | Ø50~Ø650 | width | 80~610 | 610max | ||||||

Physical properties (average values) at ambient temperature

Density [g/cm3]: 7.86

Soft Annealing

Heat to 810-850oC, cool slowly in furnace. This will produce a maximum Brinell hardness of 229.

Stress Relieving

To relieve machining stresses for greater accuracy in hardening – first rough machine, then anneal below the critical at 649/677oC a minimum of one hour at temperature and cool slowly, then finish machine.

Hardening

Harden from a temperature of 930-960oC followed by air or oil quenching. Hardness after quenching is 59-61 HRC.

Tempering

Tempering temperature: 150-400oC.

Tempering Temperature (oC) vs. Hardness (HRC)

100oC | 200oC | 250oC | 300oC | 400oC | 500oC | 550oC | 600oC | 650oC |

59 | 57 | 55 | 54 | 53 | 52 | 52 | 48 | 41 |

Forging

Hot forming temperature: 1066-1121oC.

Corrosion Resistance

Corrosion resistance of this alloy is better than that of plain carbon steels. However it will rust unless given protective treatment.